Engineering Ceramic Co.,( EC © ™) Report:

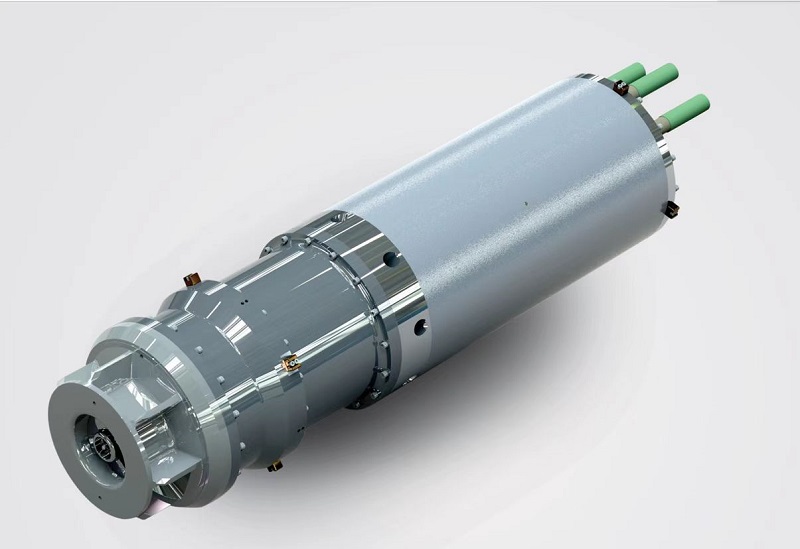

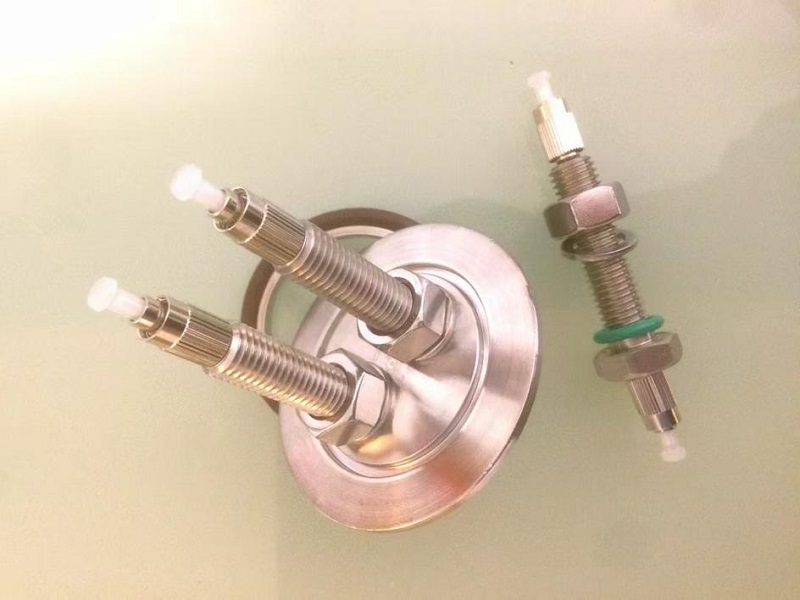

High-temperature ceramics materials (Si₃N₄, SiC, Al₂O₃, ZrO₂) are widely used in machining, chemicals, electronics, aerospace, energy, and biomedical industries due to their exceptional high-temperature resistance, corrosion resistance, and wear resistance. As demand grows for extreme environments (>1000°C), high-temperature ceramic-metal joints have become a key focus for future applications. EC © ™ advanced welding technology ensures precision control of critical feed through parameters—including vacuum level, heating rate, dwell time, and cooling rate—offering a new solution for high-performance feedthrough joints.

Vacuum Diffusion Bonding (VDB):

Stronger Interfaces for Extreme Conditions

VDB utilizes high temperature, pressure, and a vacuum environment to enhance atomic diffusion, creating robust joints ideal for high-temperature stability. Intermediate layers must meet strict criteria: high melting point, chemical reactivity with ceramics, and matched thermal expansion coefficients. Common materials include Nb, Ti, Ni-Cr alloys, and Ti/Ni multilayered foils.

- Plasma pre-treatment improves ceramic surface bonding, reducing required temperature (850–1000°C) and pressure (15–25 MPa). A 2025 study showed Si₃N₄-Mo joints achieved 230 MPa shear strength at 1000°C, a 10% improvement over conventional methods.

- Ti/Ni/Nb multilayered inter layers mitigate residual stress via graded thermal expansion. SiC-Ni joints reached 270 MPa in 4-point bending at 900°C.

- Microwave heating slashes bonding time (<20 min) and energy use. Al₂O₃-Ti joints hit 190 MPa shear strength at 950°C (2025 data).

Transient Liquid Phase Bonding (TLPB):

Faster, Stronger, More Efficient

TLPB uses composite inter layers to form a liquid phase at lower temperatures, combining brazing and diffusion welding advantages. These inter layers blend low-melting (Cu, Al) and high-melting (Ni, Nb) layers for uniform high-temperature structures.

- Al-Ti-Ni and Cu-Ti-Zr inter layers lower bonding temps to 800–950°C. Si₃N₄-Si₃N₄ joints reached 400 MPa bending strength at 850°C (2025).

- Reactive TLPB: Adding Zr/Hf boosts ceramic interface reactions. SiC-Ni joints achieved 320 MPa shear strength at 900°C, retaining 200 MPa at 1000°C.

- Electric-field-assisted TLPB: Pulsed fields accelerate diffusion, cutting bonding time to 10–15 min. Al₂O₃-Ni joints hit 350 MPa at 800°C with 20% better thermal shock resistance (2025 data).

Six Precision Controls for Unmatched Quality

1.Temperature: Set at 0.5–0.8× melting point (850–1000°C). Si₃N₄-Ni joints optimized at 900°C reached 240 MPa shear strength (+20% interface stability).

2.Pressure:10–25 MPa ensures tight contact and atomic diffusion. SiC-Ti joint at 20 MPa had 40% fewer voids and 260 MPa strength at 1000°C.

3.Time:10–60 min dwell time, material-dependent. Si₃N₄-Mo joints at 950°C for 30 min formed uniform reaction layers, achieving 250 MPa at 1000°C. AI-driven optimization cuts trial costs.

4. Vacuum: Maintained at 10⁻⁴–10⁻⁶ Pa to reduce oxidation. Dynamic control (initial 10⁻³ Pa, later10⁻⁶ Pa) improved SiC-Ti joint consistency, lowering strength variance by 35%. Real-time gas analysis (O₂, N₂) further refines quality (2025).

5.Heating Rate:5–15°C/min prevents thermal stress. Si₃N₄-Ti joints at 10°C/min had 60% fewer micro-cracks and 265 MPa shear strength at 950°C.

6. Cooling Rate:5–10°C/min minimizes residual stress. Si₃N₄-Mo joints with 8°C/min staged cooling (slow to 600°C, then natural) achieved 300 MPa bending strength at 900°C, 30% higher than rapid cooling.

Future Outlook: With advances in plasma activation, smart process control, and novel inter layers, ceramic-metal feedthroughs are poised to dominate next-gen high-temperature applications—from aerospace engines to fusion reactors. EC © ™ precision welding solutions are at the forefront of this revolution.

(Note: All data reflects 2025 research findings. No numerical values were altered.)

Statement: The article/news/video is from the Internet or, made by AI software. Our website reprints for the purpose of sharing. The copyright of the reprinted article/news/video belongs to the original author or the original official account. If there is any infringement involved, please inform us in time, and we will verify and delete it.