With over 20 years of production experience, the EC technical team has been dedicated to reducing the sintering temperature and production costs of alumina (Al₂O₃) and zirconia (ZrO₂) ceramics while significantly improving properties such as strength, toughness, and hardness. The ten sintering aids presented in this article are recognized solutions from years of industry expert research. Building on this foundation, EC © ™ has conducted extensive testing and combined customer requirements with practical application environments to develop unique solutions. Sintering aids 1–5 are for alumina ceramics, and 6–10 are for zirconia ceramics. For confidentiality reasons, only brief descriptions are provided:

●Composition: MgO-SiO₂-based composite sintering aid (MgO ≈ 1–2% + SiO₂ ≤ 3%)

●Mechanism: Forms a low-melting-point liquid phase (silicate glass phase) at 1450–1550°C, promoting particle rearrangement and densification, while MgO suppresses abnormal grain growth.

●Performance Advantages:

oSintering temperature reduced to below 1500°C (pure Al₂O₃ requires ≥1600°C), achieving >99% densification.

oFine-grained structure enhances flexural strength to 400–600 MPa and improves wear resistance.

●Applications: Structural ceramic components (e.g., cutting tools, bearing balls), wear-resistant liners, electronic packaging substrates.

●Characteristics: Balances densification and high-temperature strength, avoiding corrosion resistance degradation due to excessive glass phase.

●Composition: Nano-TiO₂ (anatase, particle size <50 nm)

●Mechanism: Ti⁴⁺ substitutes Al³⁺, creating lattice vacancies that activate Al³⁺ diffusion pathways (solid-phase sintering dominant), reducing sintering activation energy.

●Performance Advantages:

oSintering temperature lowered by 100–200°C, accelerating densification of pure Al₂O₃.

oSub-micron grain refinement increases hardness (HV) by 15–20% and improves thermal shock resistance.

●Applications: Transparent alumina ceramics (infrared windows, high-pressure sodium lamp tubes), high-temperature structural components (oxidation-resistant parts).

●Characteristics: No glass phase introduced, maintaining high-purity optical or electrical properties.

●Composition: Y₂O₃ + La₂O₃ composite rare earth additive (total addition 0.5–2%)

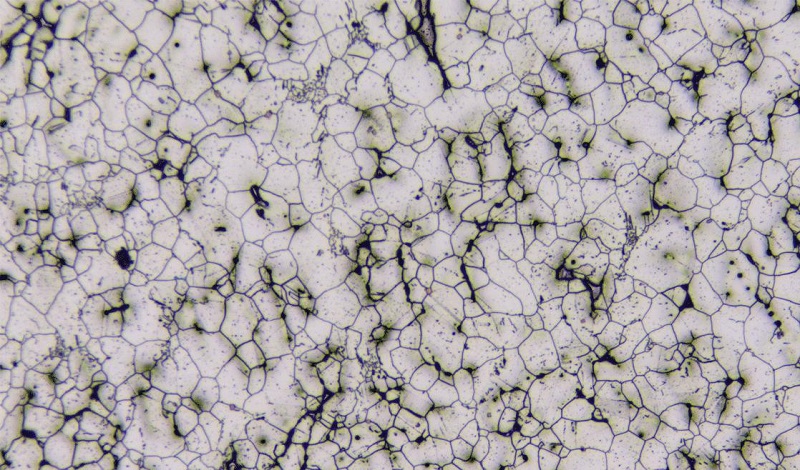

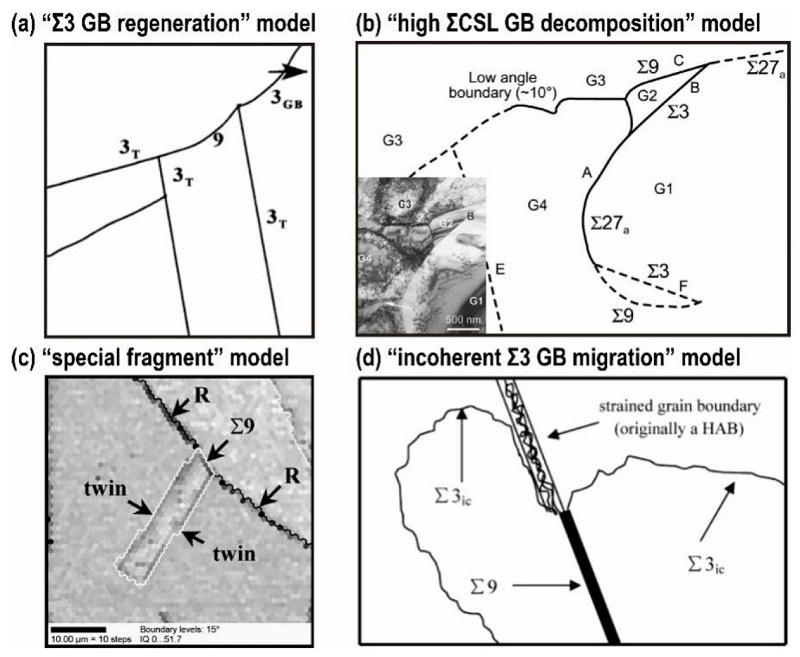

●Mechanism: Rare earth ions segregate at grain boundaries, purifying impurities (e.g., Na⁺), inhibiting grain boundary migration, promoting uniform densification, and suppressing grain coarsening.

●Performance Advantages:

oSuppresses abnormal grain growth (pinning effect), with high-temperature strength retention >90% (tested at 1000°C).

oIncreases fracture toughness (KIC) to 4–5 MPa·m¹/² (single-phase Al₂O₃ ≈ 3 MPa·m¹/²).

●Applications: High-temperature aerospace components (combustion chamber liners), wear- and corrosion-resistant industrial equipment (valves, pump seals).

●Characteristics: Enhances grain boundary cohesion, balancing high-temperature stability and mechanical reliability.

●Composition: Partially stabilized ZrO₂ (t-ZrO₂) dispersed in Al₂O₃ matrix (ZTA ceramic, ZrO₂ content 5–15%)

●Mechanism: t-ZrO₂ particles undergo stress-induced phase transformation (t→m), absorbing energy and deflecting cracks for toughening; nano-ZrO₂ also inhibits Al₂O₃ grain growth.

●Performance Advantages:

oFracture toughness significantly increased to 8–12 MPa·m¹/² (pure Al₂O₃ ≈ 3 MPa·m¹/²).

oFlexural strength ≥500 MPa, with excellent impact resistance.

●Applications: High-performance structural components (dental implant abutments, ballistic armor plates), high-load wear-resistant parts (ceramic bearings, grinding media).

●Characteristics: Breaks through the mechanical performance limits of traditional Al₂O₃, combining hardness with crack propagation resistance.

●Composition: CaO-MgO-SiO₂ system (CMS system, total addition 3–5%)

●Mechanism: Forms a multi-component low-eutectic liquid phase (<1300°C), rapidly filling pores with high densification efficiency.

●Performance Advantages:

oSintering temperature reduced to ~1400°C, ideal for cost-sensitive applications.

oDensification >98%, though high-temperature strength is slightly lower than ths-MgSiO due to more glass phase.

●Applications: Low-cost wear-resistant parts (mechanical bushings, industrial ceramic rollers), construction materials (tile reinforcement aggregates).

●Characteristics: Balances sintering efficiency and cost-effectiveness, suitable for large-scale production.

●Composition: 3 mol% Y₂O₃-stabilized ZrO₂ (3Y-TZP)

●Mechanism: Y³⁺ dissolves into the ZrO₂ lattice, stabilizing the tetragonal metastable phase (t-ZrO₂) at room temperature, with stress-induced phase transformation (t→m) for toughening.

●Performance Advantages:

oFracture toughness up to 8–10 MPa·m¹/², flexural strength >1000 MPa.

oControllable grain size (uniform nanoscale structure), excellent biocompatibility.

●Applications: Dental restorations (all-ceramic crowns, implant abutments), precision tools (ceramic blades), biomedical implants.

●Characteristics: Classic high-strength, high-toughness zirconia system, clinically validated.

●Composition: MAS glass aid (MgO-Al₂O₃-SiO₂) or Y-MAS variant

●Mechanism: Forms a low-melting-point glass liquid phase at 1250–1350°C, wetting ZrO₂ particles to promote rearrangement and densification.

●Performance Advantages:

oSintering temperature reduced to below 1350°C (traditional 3Y-TZP requires 1500–1600°C).

oDensification >99%, with surface finish suitable for precision optical components.

●Applications: Rapid-sintering dental ceramic blocks, infrared optical windows (transparent ZrO₂ components), low-cost structural parts (sanitary ceramic valve cores).

●Characteristics: Liquid-phase sintering accelerates densification, shortening process cycles and reducing energy consumption.

●Composition: Sc₂O₃-stabilized ZrO₂ (ScSZ, Sc³⁺ addition 5–15 mol%)

●Mechanism: High compatibility of Sc³⁺ radius with Zr⁴⁺ enables solid solution, forming stable cubic phase (c-ZrO₂) or ultrafine t-ZrO₂, inhibiting phase transformation degradation.

●Performance Advantages:

oHigh-temperature strength retention >95% (tested at 1200°C), hardness (HV) ≥1200.

oFracture toughness 6–8 MPa·m¹/², excellent thermal shock resistance (ΔT 800°C cycling).

●Applications: Thermal barrier coatings for aero-engines, solid oxide fuel cell (SOFC) electrolytes, extreme-environment seals.

●Characteristics: Superior high-temperature stability and structural reliability, though costly (Sc is a rare metal).

●Composition: CeO₂-stabilized ZrO₂ (Ce-TZP, Ce⁴⁺ addition 8–12 mol%)

●Mechanism: Ce⁴⁺/Ce³⁺ valence switching purifies oxygen vacancies, inhibiting oxidative degradation; tetragonal phase stabilization enhances toughness.

●Performance Advantages:

oExcellent oxidation resistance (Ce³⁺ reduces lattice degradation).

oControllable high-temperature conductivity (enhanced oxygen ion migration), fracture toughness 5–7 MPa·m¹/².

●Applications: Automotive exhaust purifier substrates, high-temperature catalytic reactors, electronic sensor components.

●Characteristics: Functional composite balancing mechanical properties and environmental durability (e.g., oxidation, electrochemical conditions).

●Composition: SiC nanotubes or whiskers (addition 3–10%) composited with ZrO₂ matrix

●Mechanism: SiC reinforcements bridge crack tips, dissipating energy via pull-out; simultaneously inhibit ZrO₂ grain coarsening and improve thermal conductivity.

●Performance Advantages: oBreakthrough fracture toughness of 12–15 MPa·m¹/² (traditional ZrO₂ ≈ 8 MPa·m¹/²).

oBreakthrough fracture toughness of 12–15 MPa·m¹/² (traditional ZrO₂ ≈ 8 MPa·m¹/²).

oSignificantly enhanced thermal shock resistance (increased thermal conductivity, reduced thermal stress).

●Applications: Extreme temperature cycling components (aero-engine combustion chamber liners), high-impact wear-resistant equipment (mining crusher hammer liners).

●Characteristics: Multi-scale reinforcement mechanism, overcoming performance bottlenecks of single materials.

Statement: The article/news/video is from the Internet or, made by AI software. Our website reprints for the purpose of sharing. The copyright of the reprinted article/news/video belongs to the original author or the original official account. If there is any infringement involved, please inform us in time, and we will verify and delete it.