Engineering Ceramic Co.,( EC © ™) Report:

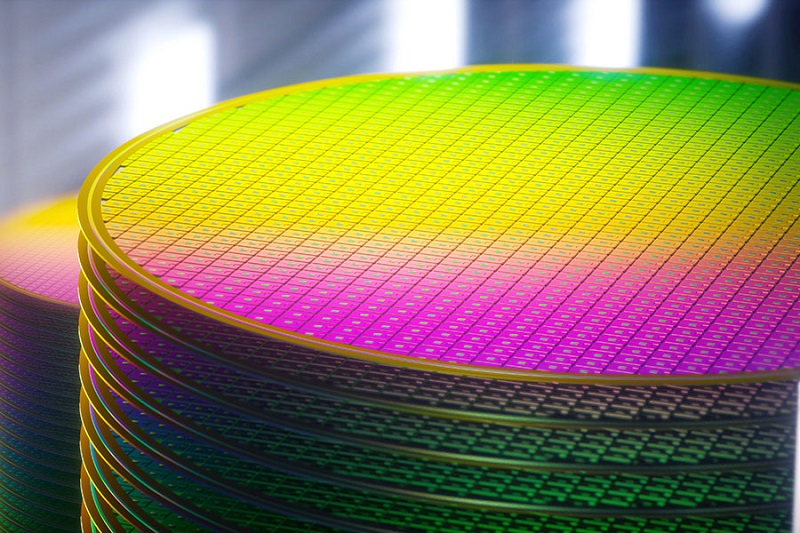

Engineering Ceramic Co proudly offers 3 distinct material types of Silicon Carbide Wafer Boats, each tailored to meet the demanding needs of advanced industries.

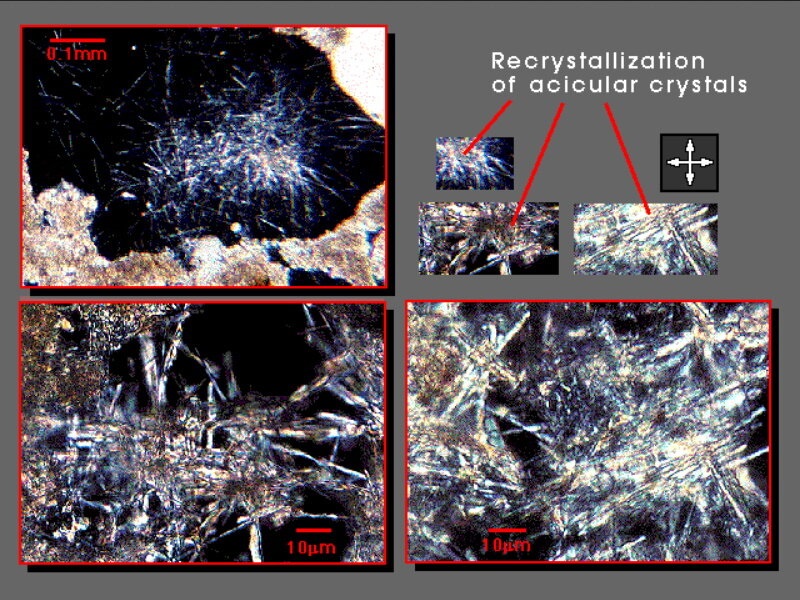

Recrystallized Silicon Carbide (RSiC) Wafer Boat with CVD-SiC Coating

Our Recrystallized Silicon Carbide Wafer Boat stands out with its sophisticated manufacturing process. The boat is meticulously crafted by dividing it into individual unit parts, sintering them separately, and bonding them with silica adhesive. These parts are then fused into a single robust structure through high-temperature firing, followed by the application of a precision CVD-SiC ceramic coating (100 µm ± 1 µm thick). This coating is essential, as the inherent porosity of recrystallized material would otherwise lead to particle contamination during operation. Unlike graphite products with CVD-SiC coatings, our RSiC Wafer Boat eliminates coefficient of thermal expansion (CTE) mismatch, ensuring a reliable service life of 2–3 years. However, the intricate process, extended production time, and elevated costs reflect the premium quality of this product.

Reaction Bonded Silicon Carbide (RBSiC) Wafer Boat

The Reaction Bonded Silicon Carbide (RBSiC) Wafer Boat, also known as silicon-infiltrated SiC (SiSiC), delivers exceptional surface density with a porosity of less than 0.1%, negating the need for additional CVD ceramic coatings. This boat is produced by blending SiC and Si powders, casting them into shape, sintering them into a cohesive unit, and finishing with precision CNC machining. While SiC’s hardness and brittleness pose challenges—resulting in a higher scrap rate and elevated production costs—the outcome is a durable product. Compared to quartz, which offers lower costs through segmented processing and melting, RBSiC contains 10–15% free Si, limiting its maximum operating temperature to below 1350°C (the melting point of Si). Additionally, its susceptibility to HF corrosion can lead to particle contamination, a factor to consider for specific applications.

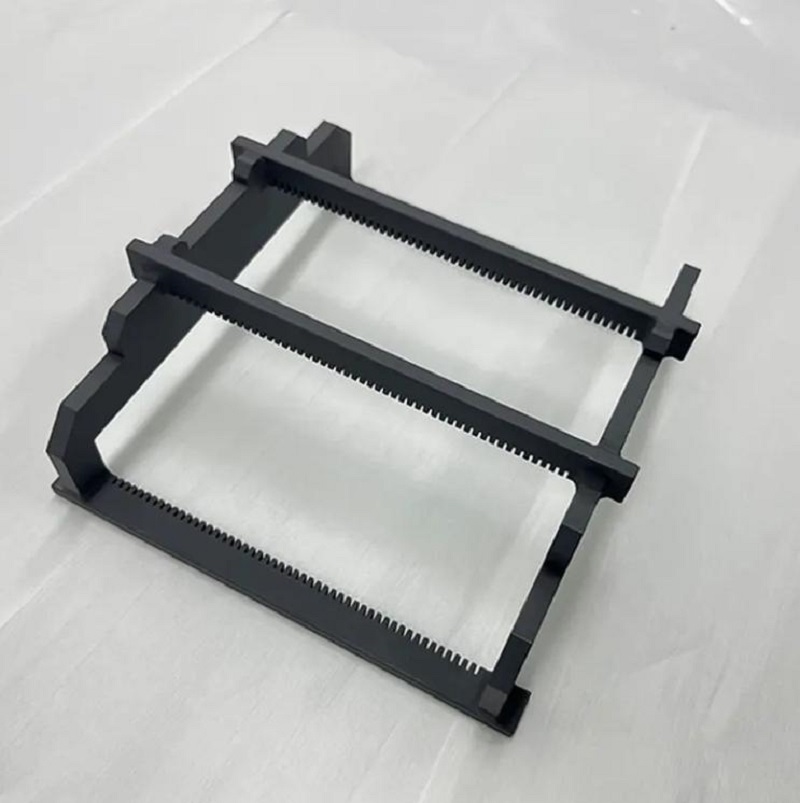

Sintered Silicon Carbide (SSiC) Wafer Boat

Our Sintered Silicon Carbide (SSiC) Wafer Boat, crafted from pressureless sintered SiC with a purity of 99.5% min, represents the pinnacle of performance. The manufacturing process—casting, sintering, and CNC machining—culminates in an assembly secured with custom SSiC screws, nuts, and pins, optimizing load-bearing strength. With virtually zero porosity, this boat requires no additional coatings and is immune to particle contamination. It excels in extreme conditions, supporting a maximum operating temperature of 1600°C and exceeding 1800°C in vacuum environments. Renowned for its superior corrosion resistance, especially in high-temperature and harsh corrosive settings, the SSiC Wafer Boat offers an impressive service life of over 5 years, making it an ideal choice for the most demanding applications.

Over the course of more than 20 years of SiC product manufacturing, EC has accumulated extensive production experience and practical expertise. We deliver to our customers stable products, reliable technical support, and 24/7 uninterrupted service. For detailed product manuals, technical inquiries, pricing, and inventory information, please contact us.

Statement: The article/news/video is from the Internet or, made by AI software. Our website reprints for the purpose of sharing. The copyright of the reprinted article/news/video belongs to the original author or the original official account. If there is any infringement involved, please inform us in time, and we will verify and delete it.