Engineering Ceramic Co.,( EC © ™) Report:

EC Vacuum Feedthroughs – Technical Overview

EC specializes in high-performance vacuum feedthroughs featuring:

✔ Ceramic insulators (Al₂O₃/AlN) for ultra-high voltage isolation

✔ Vacuum brazing technology (leak rate <10⁻⁹ mbar·L/s)

✔ Hermetic sealing for turbomolecular/ion pumps (UHV/XHV compatible)

✔ Custom configurations for semiconductor, aerospace, and research applications

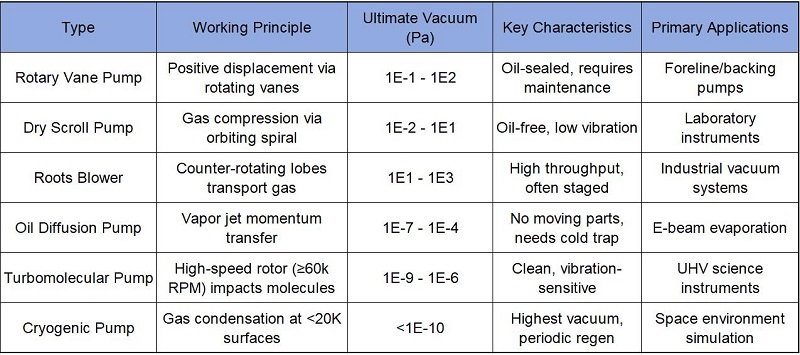

Table 1: Classification by Working Principle

Table 2: Classification by Vacuum Level

Key Selection Criteria

1.Ultimate Vacuum Level

The required vacuum level should align with process specifications. For example: Semiconductor manufacturing typically requires vacuum levels below 10⁻⁶ Pa Industrial processes may operate effectively in the 10⁻¹ to 10² Pa range

2.Pumping Speed

Measured in liters per second (L/s) or cubic meters per hour (m³/h) Must be sized appropriately for the chamber volume and gas load High-throughput applications (e.g., vacuum furnaces) may require 1,000+ m³/h

3.Gas & Chemical Compatibility

●Standard applications: Standard materials (stainless steel, aluminum)

●Corrosive environments: Requires specialized materials such as:

●PTFE-coated components (for acid resistance)

●Hastelloy or nickel alloys (for aggressive chemistries like chlorine)

4.Energy Efficiency & Maintenance

Oil-sealed pumps:

●Lower initial cost

●Require regular oil changes (every 2,000–4,000 hours)

●Risk of oil contamination in sensitive processes

Dry (oil-free) pumps:

●Higher initial investment

●Maintenance-free operation (no oil changes)

●Preferred for clean processes (e.g., pharmaceuticals, food)

Statement: The article/news/video is from the Internet. Our website reprints for the purpose of sharing. The copyright of the reprinted article/news/video belongs to the original author or the original official account. If there is any infringement involved, please inform us in time, and we will verify and delete it.