Engineering Ceramic Co.,( EC © ™) Report:

Understanding Vacuum Chamber Leaks: Prevention and Detection with Reliable Feedthrough

At Engineering Ceramic Co Ltd (EC), we specialize in high-quality industrial feedthroughs designed for vacuum equipment, ensuring optimal performance and reliability in demanding applications. This week's news explores common causes of vacuum chamber leaks, methods for detection, and the essential role of feedthroughs in maintaining vacuum integrity—drawing insights from industry discussions on leak management.

Common Causes of Vacuum Chamber Leaks

Vacuum chambers are critical in various industrial processes, but leaks can compromise their effectiveness, leading to reduced efficiency, contamination, or system failure. Based on expert analyses, leaks often stem from:

- Poor Seals and Workmanship Issues: Improper installation or defects in seals, such as O-rings or gaskets, can create pathways for air ingress. Virtual leaks—trapped gas pockets within the chamber due to design flaws or material laminations are particularly insidious as they release gas slowly over time.

- Material Defects and Damage: Cracks in chamber walls, feedthrough failures, or damage from shipping/handling can introduce leaks. Dirty or degraded seals exacerbate the problem.

- Component Failures: Loose valves, faulty flanges, or inadequate feedthroughs that fail to maintain a hermetic seal under pressure and temperature variations.

These issues highlight the need for robust components to prevent downtime and ensure process stability.

Detecting Leak Points: Effective Methods

Identifying leaks promptly is key to maintaining vacuum systems. Common detection techniques include:

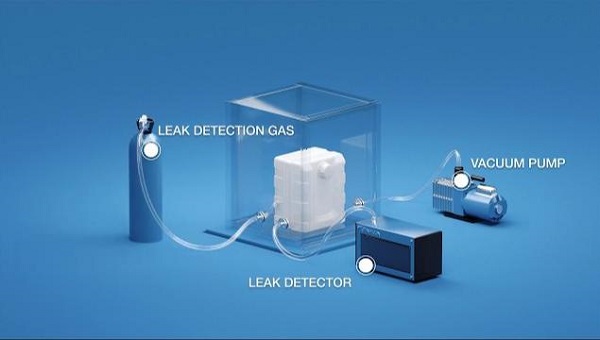

- --Helium Leak Detection--: Introduce helium as a tracer gas on one side of the chamber and use a mass spectrometer to detect it on the other. This method is highly sensitive and accurate for pinpointing even small leaks.

- --Pressure Rise Test--: Monitor the rate of pressure increase in the chamber after isolation to differentiate between real leaks and outgassing.

- --Other Techniques--: For accessible systems, soapy water sprays can reveal bubbles at leak sites, though this is less common in high-vacuum environments. Advanced partial pressure analysis with mass spectrometers can further isolate causes.

Regular inspections and using reliable tools can minimize disruptions in vacuum-dependent operations.

Basics of Industrial Feedthroughs in Vacuum Equipment

Industrial feedthroughs are vital components that enable the transfer of electrical signals, mechanical motion, fluids, or gases across vacuum barriers without compromising the seal. Here's a quick overview:

- --Definition and Function--: A vacuum feedthrough is an assembly that passes substances or energy from outside a sealed chamber to the inside, remaining leak-free under extreme conditions like high pressure, temperature, and vacuum levels.

- --Types--:

- Electrical feedthroughs for power and signals.

- Fluid/gas feedthroughs for cooling or actuation.

- Rotary feedthroughs for transferring motion.

- --Key Features--: Designed for reliability, they must handle specific materials, temperatures, and pressures to prevent leaks—making them essential in industries like semiconductors, aerospace, and scientific research.

Poorly designed feedthroughs can be a common leak source, emphasizing the importance of high-quality solutions.

EC’s Commitment to Leak-Proof Solutions

At EC, our ceramic-based industrial feedthroughs are engineered to exceed industry standards, providing hermetic seals that minimize leak risks in vacuum equipment. By integrating advanced materials and precision manufacturing, we help clients avoid common pitfalls like those discussed above.

For more information on our feedthrough products or to discuss your vacuum system needs, visit feed through insulators or contact our team. Stay tuned for more insights on optimizing your industrial processes!

Keywords: #Titanium Metal #Aerospace Titanium #Titanium Sponge #VSMPO AVISMA #Baoti Group #Titanium Alloy #Russia Titanium Export #China Titanium Production #Titanium Industry #Titanium Processing

#Titanium Ingot #Global Titanium Market #Titanium Supply Chain

#Titanium Applications #Military Titanium Alloy #Titanium Price

#Lightweight Metals #Titanium Smelting #Titanium Resources

#Green Titanium Manufacturing #Material innovation, # Engineer Ceramic #Advantage Ceramic #Alumina Ceramic #Rare Earth # Vacuum Chamber Leaks

# Leak Detection Methods # Industrial Feedthroughs# Hermetic Seals# Helium Leak Testing

# Pressure Rise Test # Virtual Leaks # Ceramic Feedthroughs # Vacuum Equipment

# Engineering Ceramic Co Ltd

Statement: The article/news/video is from the Internet or, made by AI software. Our website reprints for the purpose of sharing. The copyright of the reprinted article/news/video belongs to the original author or the original official account. If there is any infringement involved, please inform us in time, and we will verify and delete it.