Engineering Ceramic Co.,( EC © ™) Report:

the Defense and Military Industry Special ceramic materials

Keywords: #Special ceramic materials, #Defense and military industry, #High performance, #Alumina, #Engineering application, #Reliability evaluation, #Complex components, #Brittleness, Aerospace, #Ordnance equipment, #thermal protection system, #Engine performance, #Thermal barrier coating, #Ceramic bearings, #Composite armor, #Piezoelectric ceramics, #Nuclear energy equipment, #Electromagnetic protection,# New energy vehicles, #Material innovation, # Engineer Ceramic #Advantage Ceramic #Alumina Ceramic #Rare Earth

# Special Ceramic Materials: The Key Force in the Defense and Military Industry Special ceramic materials play a significant role in the defense and military industry due to their characteristics such as high strength, high temperature resistance, and corrosion resistance. China attaches great importance to their development, and high-performance ceramic materials are listed as one of the key basic materials in the "14th Five-Year Plan for the Development of the Defense Science, Technology and Industry".

China's special ceramic field has an early start. Special ceramic materials based on alumina have achieved engineering applications. For example, the Al₂O₃-TiC composite ceramic cutting tools produced by a certain company have a significantly longer service life than cemented carbide. An enterprise has developed boron carbide ceramic armor, which can effectively resist the penetration of armor-piercing projectiles while reducing the areal density. However, compared with the international advanced level, there are still gaps in aspects such as the reliability evaluation system of ceramic materials and the forming technology of complex components, and the brittleness problem of materials also needs to be overcome.

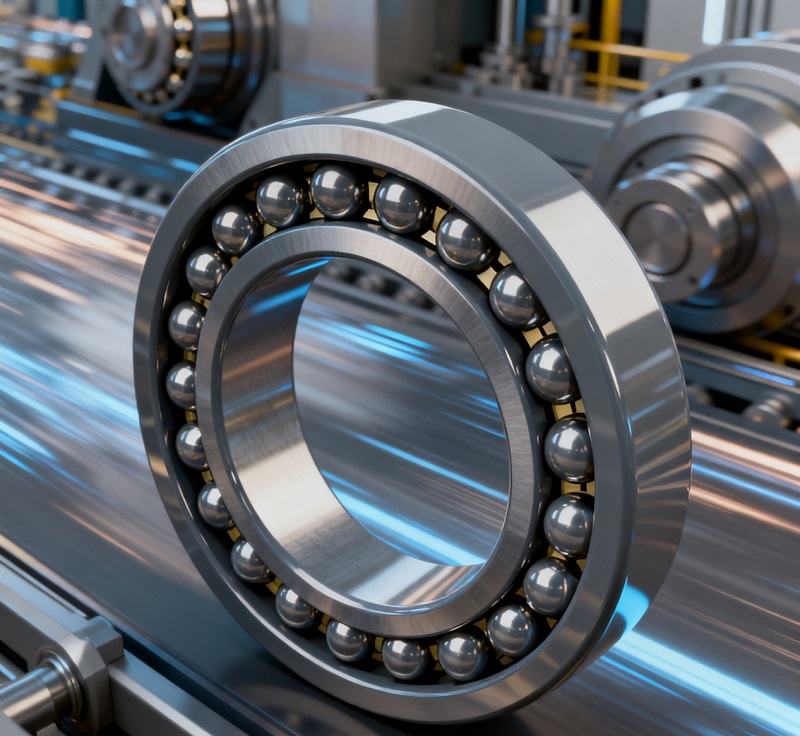

In various fields of the defense and military industry, special ceramic materials are widely used. In the aerospace field, the ZrB₂-SiC-ZrC ternary ceramic matrix composites are used in the thermal protection system of hypersonic vehicles. The C/C-SiC composites are applied to the engines of the Long March 5 carrier rocket, improving the performance of the engines. The 8% Y₂O₃-stabilized ZrO₂ thermal barrier coating extends the service life of the hot-end components of the engines. Meanwhile, silicon nitride ceramic bearings, BN-SiO₂ composite ceramic radomes, and Al₂O₃-TiC ceramic reducers have promoted the lightweight and intelligent development of spacecraft. In the field of ordnance equipment, B₄C/Al composite armor, AlN ceramic interlayer reactive armor, and SiC/polymer composite bulletproof plates play important roles in armor protection, anti-armor-piercing, and helicopter cockpit protection respectively. WC-Co ceramic matrix composite armor-piercing projectile cores, PZT-5H piezoelectric ceramic fuzes, and MgAl₂O₄ transparent ceramic missile seeker windows have expanded the functions of ammunition and fuze systems.

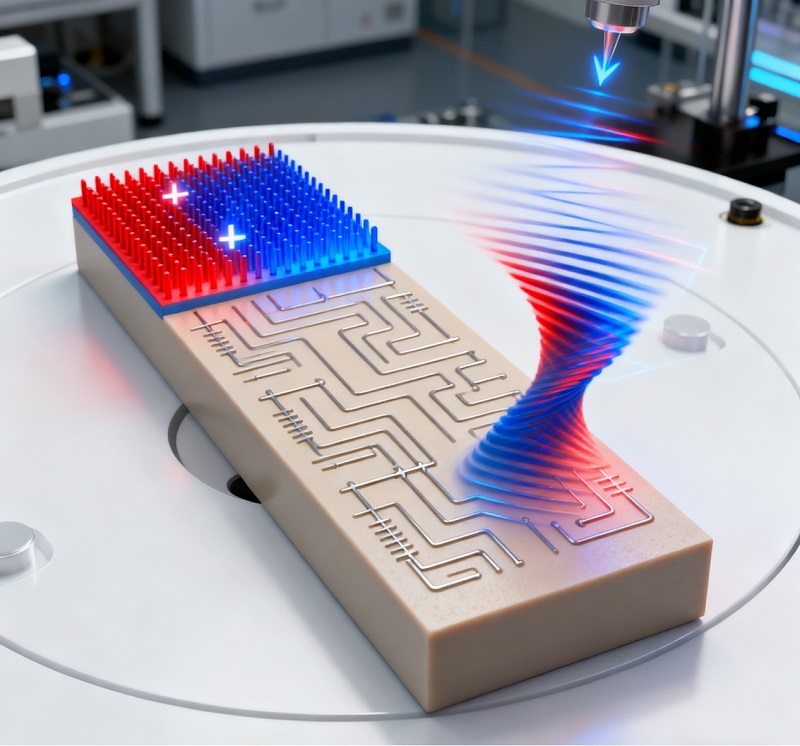

In other defense fields, PMN-PT-based piezoelectric ceramics are used in ship sonar systems to improve detection performance. Boron carbide is used in the control rods of nuclear energy equipment reactors to ensure the safe operation. Silicon carbide fiber-reinforced ceramic matrix composites are used for electromagnetic protection to enhance the electromagnetic compatibility of equipment.

Engineering Ceramic Co., Ltd and National Machinery Group has mastered the synthesis technology of silicon nitride powder through independent research and development, breaking the foreign monopoly. Its related products are applied in fields such as new energy vehicles and aerospace, and its technological research and development have promoted the upgrading of the new energy vehicle industry chain.

In the earlier of 2025, both above teams has mastered the full set of technical processes for special ceramics. Its products are applied in industrial, civil and protective equipment fields, and it has achieved outstanding results in the field of protective equipment ceramics. It has participated in the drafting of many standards and is actively exploring new fields such as photovoltaics and semiconductors. In the future, the development of China's special ceramic materials should focus on the innovation of material systems, explore the potential of high-entropy ceramics and ultra-high temperature ceramics, optimize preparation technologies to solve the bottleneck of 3D printing, and develop functional ceramic materials to improve the intelligence level of equipment, thus promoting the continuous development of China's defense and military industry.

Statement: The article/news/video is from the Internet or, made by AI software. Our website reprints for the purpose of sharing. The copyright of the reprinted article/news/video belongs to the original author or the original official account. If there is any infringement involved, please inform us in time, and we will verify and delete it.